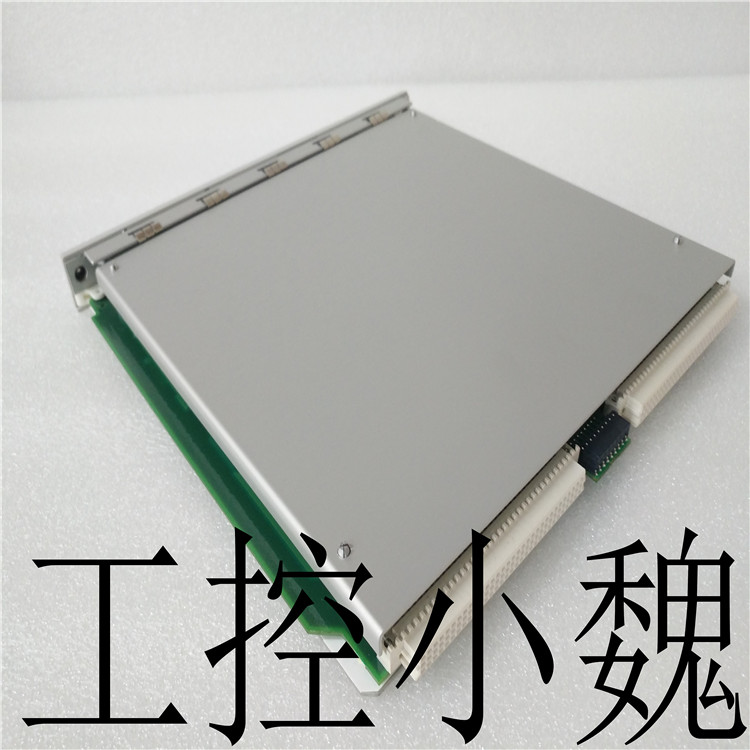

¥5252.00 库存:12 举报

SEWMDV自动化备件模块维护SEW

品牌:SEW

型号:SEWMDV

货期: 现货 1天内发货

联系我时,请告诉我是在易卖工控网看到的,谢谢!

联系热线: 18030177759

幻花自动化

![]() 3年

3年

描述5.0 服务5.0 物流5.0

——— 宝贝详情 ———

SEWMDV关于数字化和智能制造,不同的企业有不同的战略和方向。对于ABB中国运动控制事业部来说,我们已经在中国交付了1000多万台的电机和变频器,所以如何将这些设备更多地与互联网相连是我们的首要任务。与此同时,我们也积极地寻找各行业的领军企业进行合作,共同开发针对行业的数字化解决方案。除此之外,数字化发展也与渠道网络的建立息息相关,所以我们也在积极开发并完善数字化的渠道网络覆盖。本土企业不断壮大,它的响应速度可能更快,在这种竞争格局下,ABB将如何更快地将创新成果推向市场?坚持以客户为中心,为客户创造更多的价值,是我们一直以来的关注重点。

ABB运动控制在中国开展业务已经有超过25年的时间了,所以我们非常适应中国速度。我们的业务发展一直与中国的发展是同步的,并致力于将自身的工作重点从销售和制造向研发、创新和数字化方面转移。对于即将到来的2022年,ABB运动控制的业务重点和发展战略又是什么?2022年,ABB运动控制将始终坚持以客户为中心的原则,继续大力发展重大战略性项目基于当前波动的市场形势和疫情的反复态势,市场仍存在很多不确定性。2022年,ABB运动控制将始终坚持以客户为中心的原则,继续大力发展重大战略性项目。我们未来要继续抓住每一个可能的市场机会,不断开发各个行业中的新客户新应用,同时加强产品和技术创新,提高生产效率,不断巩固稳定回升的态势,持续贯彻节能增效、低碳减排的理念,促进社会和智能制造的转型。1、ABB机器人伺服电机修理几种故障在有脉冲输出时不工作,怎么处理?

监督操控器的脉冲输出当时值以及脉冲输出灯是否闪烁,承认指令脉冲现已履行并现已正常输出脉冲;查看操控器到驱动器的操控电缆,动力电缆,编码器电缆是否配线过错,破损或许接触不良;查看带制动器的伺服电机其制动器是否现已翻开;监督伺服驱动器的面板承认脉冲指令是否输入;Run运转指令正常;操控形式必须挑选方位操控形式;伺服驱动器设置的输入脉冲类型和指令脉冲的设置是否共同;确保正转侧驱动制止,回转侧驱动制止信号以及差错计数器复位信号没有被输入,脱开负载而且空载运转正常,查看机械体系。

2、ABB机器人伺服电机修理几种故障高速旋转时出现电机差错计数器溢出过错,怎么处理?

高速旋转时发作电机差错计数器溢出过错。

对策:查看电机动力电缆和编码器电缆的配线是否正确,电缆是否有破损。

输入较长指令脉冲时发作电机差错计数器溢出过错。

对策:增益设置太大,从头手动调整增益或运用主动调整增益功能;延长加减速时间;负载过重,需求从头选定更大容量的电机或减轻负载,加装减速机等传动组织提高负荷才能。

运转过程中发作电机差错计数器溢出过错。

对策:增大差错计数器溢出水平设定值;减慢旋转速度;延长加减速时间;负载过重,需求从头选定更大容量的电机或减轻负载,加装减速机等传动组织提高负载才能。

As for digitalization and intelligent manufacturing, different enterprises have different strategies and directions. For ABB China Motion Control Business Unit, we have delivered more than 10 million motors and frequency converters in China, so how to connect more of these devices to the Internet is our top priority. At the same time, we are also actively looking for leading enterprises in various industries to cooperate and jointly develop digital solutions for the industry. In addition, digital development is also closely related to the establishment of channel networks, so we are also actively developing and improving digital channel network coverage. With the continuous growth of local enterprises, its response speed may be faster. Under this competitive situation, how will ABB bring its innovative achievements to the market faster? We have always focused on customer focus and creating more value for customers.

ABB Motion Control has been doing business in China for more than 25 years, so we are very adapted to the speed in China. Our business development has been synchronized with that of China, and we are committed to shifting our focus from sales and manufacturing to R&D, innovation and digitalization. What are the business priorities and development strategies of ABB Motion Control in the coming 2022? In 2022, ABB Motion Control will always adhere to the customer-centric principle and continue to vigorously develop major strategic projects. Based on the current volatile market situation and the repeated epidemic situation, there are still many uncertainties in the market. In 2022, ABB Motion Control will always adhere to the customer-centric principle and continue to vigorously develop major strategic projects. In the future, we will continue to seize every possible market opportunity, continue to develop new customers and applications in various industries, strengthen product and technological innovation, improve production efficiency, continue to consolidate the trend of stable recovery, continue to implement the concept of energy conservation and efficiency enhancement, low-carbon emission reduction, and promote the transformation of society and intelligent manufacturing. 1. ABB robot servo motor repairs several faults and does not work when there is pulse output. How to deal with them?

Monitor the current value of the pulse output of the controller and whether the pulse output light flashes, and acknowledge that the command pulse has been fulfilled and the pulse has been output normally; Check whether the control cable, power cable and encoder cable from the controller to the driver are wrongly wired, damaged or in poor contact; Check whether the brake of the servo motor with brake has been turned over; Supervise whether the panel of the servo driver acknowledges whether the pulse command is input; Run operation command is normal; The azimuth control form must be selected; Whether the input pulse type and command pulse set by the servo driver are the same; Make sure that the drive stop signal at the forward rotating side, the drive stop signal at the rotating side and the error counter reset signal are not input, disconnect the load and operate normally without load. Check the mechanical system.

2. How to deal with the motor error counter overflow fault when ABB robot servo motor repairs several faults and rotates at high speed?

Motor error counter overflow fault occurs when rotating at high speed.

Countermeasures: Check whether the wiring of motor power cable and encoder cable is correct and whether the cable is damaged.

The motor error counter overflow fault occurs when a long command pulse is input.

Countermeasures: If the gain setting is too large, manually adjust the gain from the beginning or use the active gain adjustment function; Extend acceleration and deceleration time; If the load is too heavy, it is necessary to select a motor with larger capacity from scratch or reduce the load, and install a transmission organization such as a reducer to increase the load.

Motor error counter overflow fault occurs during operation.

Countermeasures: Increase the set value of error counter overflow level; Slow down the rotation speed; Extend acceleration and deceleration time; If the load is too heavy, it is necessary to select a motor with larger capacity from scratch or reduce the load, and install a transmission organization such as a reducer to increase the load capacity.

安全提示:

请勿随意接收任何来源不明的文件,请勿随意点击任何来源不明的链接。涉及资金往来的事项请务必仔细核对资金往来信息。

——— 猜你喜欢 ———

X

¥5252.0

库存:12