¥45455.00 库存:8 举报

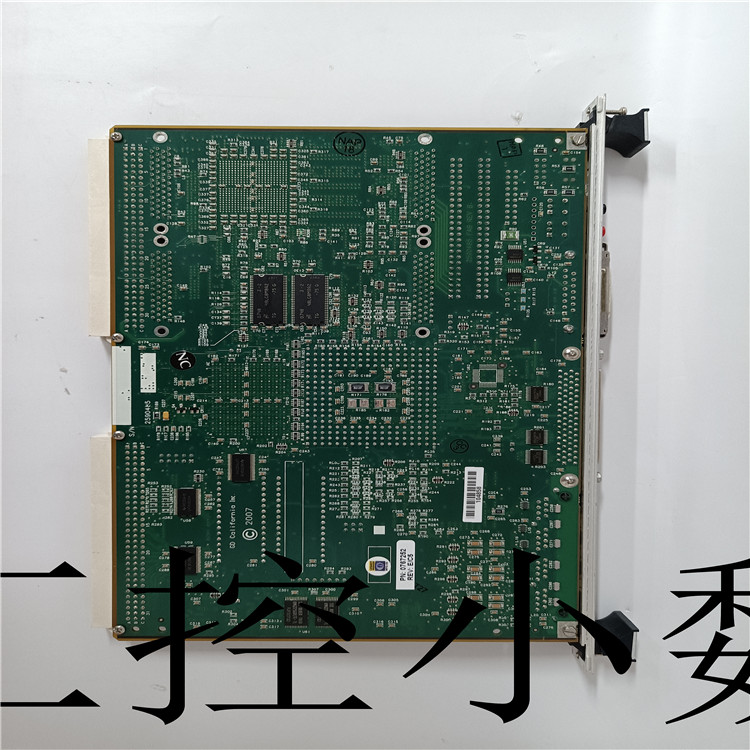

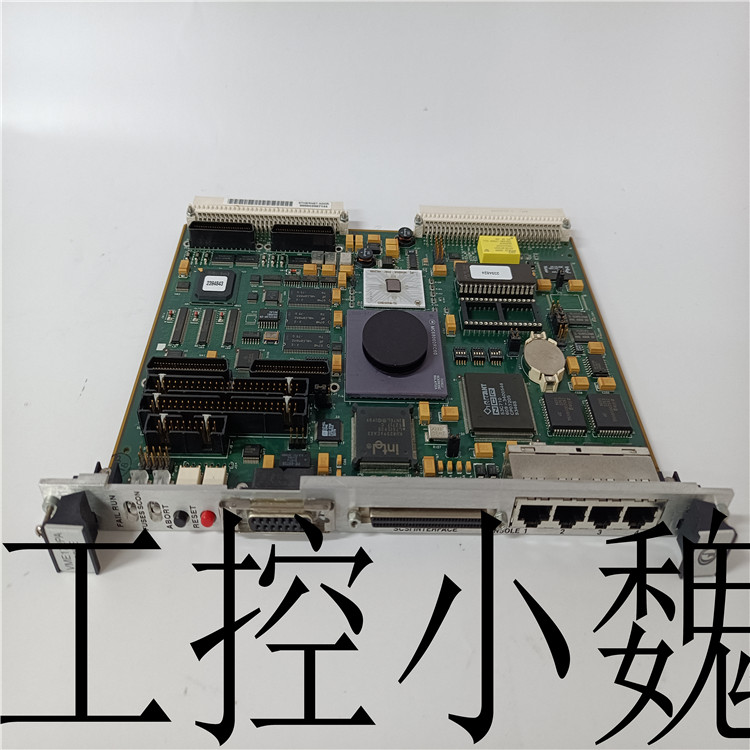

IS200VRTDH1DAC模块GE

品牌:GE

型号:IS200VRTDH1DAC

货期: 现货 1天内发货

联系我时,请告诉我是在易卖工控网看到的,谢谢!

联系热线: 18030177759

工业备件直营超市

![]() 6年

6年

描述5.0 服务5.0 物流5.0

——— 宝贝详情 ———

IS200VRTDH1DAC多年环网柜设计、制造和运行经验出发,开发出众多具有针对性的智能监测和诊断算法,用以实现设备由周期性运维到状态运维和预测性运维的转变,从而减少现场运维工单的派遣,节约人力。ABB基于真实设备数据的算法开发,大幅提高了监测诊断的准确率,更率先提出了自学习动态阈值的理念,直面设备个体差异,实现阈值的实时调整、自动调整,精准识别判断设备运行状态,让设备运维更省心夏日是度假休憩的季节,如何能顶着炎炎烈日、在设备前稳坐如钟?ABB多样化用户交互手段让你不再苦守现场一卷到底,远程亦可便捷进行信息交互,不被工作束缚远行的步伐,轻松享受盛夏。

ABB数字智能环网柜Safe Digital可以自由接入ABB Ability™ 云端平台,实现数据的远程访问,多种数据查看途径让你随时随地掌控设备情况:可通过柜体上的显示屏,查看所有设备运行数据和设备健康状态;可通过扫描0,使用手机连接智能终端WiFi,通过手机浏览设备监测实时数据;可搭乘“云边融合”的快车,通过ABB Ability™云端平台(或客户私有平台)查看数据情况。重要事件信息及时推送到客户订阅手机号,实现设备状态“零延时”掌握。ABB数字智能环网柜Safe Digital不仅性能优越,还在设计中考虑了易更换性,便于二次设备升级改造。通过更简单的计划和更少的改造投入实现设备全寿命周期的成本降低,全面呵护客户的资产健康,提高客户资产的投资价值。

具有出色 TFT/LED 显示颜色和多协议连接性的触摸屏面板。它们是易于使用的 HMI,具有全面和集成的模板和库,适用于您需要的每个可能的过程。所有标准面板均配备 TFT/LED 显示屏中的高分辨率图形。大多数型号提供宽屏、高分辨率显示屏,以提高效率和出色的操作员交互。

。完全可部署的 HMI,具有适用于每个可以想象的过程的全面和集成的模板和库。Panel Builder 工具具有熟悉的 Microsoft® Windows® 环境以及多语言支持,可实现快速、简单和高效的工程设计。81001-450-53-R当写入该字段时,定时器4在下一次上升时加载写入的值计时器时钟的边缘,无论计时器是启用还是禁用。这个存储在该寄存器中的值也会在终端计数时自动重新加载(或超时)。读取任一字段时,当前计数值被锁定并返回。有两种模式确定如何锁定计数,具体取决于WDT控制状态寄存器(CSR2)中的“读取锁存选择”位。参见CSR2有关这两种模式的更多信息,请注册说明。读取此字段时,当前计数值被锁定并返回。有两种模式确定如何锁定计数,具体取决于WDT控制状态寄存器(CSR2)中的“读取锁存选择”位。参见CSR2有关这两种模式的更多信息,请注册说明。定时器4电流计数寄存器(TMRCCR4)定时器4的电流计数可通过定时器4电流计数寄存器读取(TMRCCR4),位于BAR2中地址的偏移量0x28处81001-450-53-R A-B高压变频器模块

I.中央处理单元(CPU)

中央处理单元(CPU)是PLC的控制中枢。它按照PLC系统程序赋予的功能接收并

存储从编程器输入的用户程序和数据,检查电源、存储器、VO以及警戒定时器的状态,

并能诊断用户程序中的语法错误:当PLC投入运行时,首先它以扫描的方式接收现场各输

入装置的状态和数据,并分别存入IO映像区,然后从用户程序存储器中逐条读取用户程

序,经过命令解释后,按指令的规定将逻辑或算术运算的结果送入Vo映像区或数据寄存

器内。等所有的用户程序执行完毕之后,0后将1/O映像区的各输出状态或输出寄存器内

的数据传送到相应的输出装置,如此循环运行,直到停止运行为止。

为了进一步提高PLC的可靠性,近年来对大型PLC还采用双CPU构成冗余系统,或

采用三CPU的表决式系统。这样,即使某个CPU出现故障,整个系统仍能正常运行。

2.存储器

存放系统软件的存储器称为系统程序存储器。

(1) PLC常用的存储器类型。

1) RAM (Random Assess Memory)。这是-一种读/写存储器(随机存储器)其存取速

度0快,由铿电池支持。

2) EPROM (Erasable Progranmable Read Only Memory)。这是一种可擦除的只读存储

器在断电情况下存储器内的所有内容保持不变(在紫外线连续照射下可擦除存储器内容)。

3) EPROM (Electrical Erasable Programmable Read Only Memory)。这是一种电可擦

除的只读存储器。使用编程器就能很容易地对其所存储的内容进行修改。

(2) PLC存储空间的分配。虽然各种PLC的CPU的0大寻址空间各不相同,但是根

据PLC的工作原理其存储空间一般包括以下三个区域:系统程序存储区、系统RAM存储

区(包括I/O映像区和系统软设备等)、用户程序存储区。

1)系统程序存储区。在系统程序存储区中存放着相当于计算机操作系统的系统程序,

包括监控程序、管理程序、命令解释程序、功能子程序、系统诊断子程序等。由制造厂商

将其固化在EPROM中,用户不能直接存取。它和硬件一起决定了 该PLC的性能。

2)系统RAM存储区。系统RAM存储区包括I/O映像区以及各类软设备,如:逻辑

线圈、数据寄存器、计时器、计数器、变址寄存器、累加器等存储器。组态控制技术属于一种计算机控制技术。它是利用计算机监控某种设备使其按照控制要求工作。利用组态控制技术构成的计算机组态监控系统主要由被控对象、传感器、I/O接口、计算机及执行机构等部分组成。

本次实训是借助MCGS组态软件平台来完成组态监控系统人机界面制作和程序的设计的。MCGS(Monitor and Control Generated System, 通用监控系统)组态软件是北京昆仑通态软件公司研发的基于Window平台的,用于快速构造和生成上位机监控系统的组态软件系统。通过对现场数据的采集处理,以动画显示、报警处理、流程控制、报表输出等和多种方式向用户提供解决实际工程问题的开发平台。

由于是国人开发的软件,所以它是全中文的,很适合我们使用,还有它可提供近百种绘图工具和基本图符,快速构造图形界面,此外还提供上千个精美的图库元件及渐进色等多种

动画方式可以快速的构建精美的动画,它还支持温控曲、计划曲线、时实曲线、历史曲线、XY等多种工控曲线。总之使用MCGS软件可以较快速的完成一个运行稳定、功能成熟、维护量小并且具备专业水准的计算机监控控制系统的开发工作。下面我来介绍在使用MCGS组态软件来完成任务的详细过程及遇到的问题和解决的办法。

任务一 水泵运行控制

打开MCGS通用版组态软件,我们会看见5个部分,分别为主控窗口、设备窗口、用户窗口、实时数据库和运行策略。

首先我们先新建一个工程,将其命名为水泵控制系统并进行保存。

然后打开用户窗口完成相关图符的建立,老师在建工程时先建立了实时数据库,是因为对图符的控制属性有较清楚的认识,所以对于初学者来说,先画图符是0先的选择。

(1)在用户窗口中新建一个窗口0,并将其重命名水泵运行控制,在动画窗口中用标签建立动画的标题“水泵控制”

(2)绘制水泵

在软件中,已经为我们提供了“对象原件库”我们可以在其中选择所要的原件,所以接下来添加一个“泵30”图符再确定,可以调节图符的大小,以至达到美观的效果

(3)在泵下面添加两个“按钮”分别将名称改为“启动”和“停止”也可以双击来改变按钮的背景颜色。

(4)因为要展示停止和启动时的状态所以再添加两个指示灯,为了更为清楚的展现启动和停止的状态,也可以自己改造一个指示灯,其改造方法为先用一个库提供的指示灯作为改造对象先分解单元在将0前面的图符拖走,将底层的图符分解图符再改变其颜色和添加一个“可见度”属性并在表达式里填入@开关量,然后再对另一只指示灯做相关属性的设置。

(5)为了显示时间我们再添加两个按钮分别为“定时器启动”和“定时器复位”再添加 两个标签分别为控制“计时时间”和“时间到”。

(6)添加四个输入框将其属性设置为数值型,

(7)现在我们来进行实时数据库里相关数据的添加,分别为 水泵、启动、复位、定时器启动、定时器复位都是开关量,而“计时时间”和“时间到”为数值型。

(8)实时数据建立完成后,再进行用户窗口里图符的相关表达式的关联,由于要有时间控制所以在运行策略里我们要添加一个定时器,和一个脚本程序,在定时器属性里设置时间值为35秒,在脚本程序里用IF-THEN语句来编写控制程序。记住要用EXIT来划分步骤,在0后要进入运行环境测试前,应调节循环策略的属性,将定时循环时间改为200s。

任务二 水泵运行监控

前期仅是利用MCGS系统的“设备无关性”在水泵控制组态工程中借助定时器和脚本策略,初步实现了水泵控制系统的模拟运行,并未达到实时监控的目的,所以接下来要监控设置。

我们知道,水泵运行控制主要是使用PLC来控制的,而MCGS系统,一方面需要从PLC采集相关数据,改变实时数据库中对应变量的值,然后以画面中图符构件的动画形式显示出来,从而达到监视运行的目的;另一方面还需要将上位机组态环境中设置的暂停和运行时间写入PLC中,实现对水泵运行时间到调整,以及通过上位机启动和停止按钮实现对水泵硬件系统的运行和停止的控制。

打开前一个“任务一”将其另存为“水泵运行监控”在将“任务一”组态工程动画及属性设置进行改进。

(1)删除定时器策略及脚本程序策略。【在联机时,PLC完成控制任务,所以组态工程

中的定时器和脚本程序就无用了】

(2)修改数据库中与定时器相关的4个数据对象,分别为“定时器启动”“定时器复位”计时时间和时间到,以提高运行环境效率。然后在添加4个新的数据对象,分别为“运行时间显示”、“运行时间调整”、“暂停时间显示”和“暂停时间调整”,对象类型为数值型。

(3)在“动画组态水泵控制”窗口中删除与定时器相关的图符,并且制作6个新的文字标签。

(4)制作如图的动画窗口。Based on years of experience in the design, manufacturing and operation of ring network cabinets, abb has developed many targeted intelligent monitoring and diagnosis algorithms to realize the transformation of equipment from periodic operation and maintenance to state operation and maintenance and predictive operation and maintenance, so as to reduce the dispatch of on-site operation and maintenance orders and save manpower. ABB's algorithm development based on real equipment data has greatly improved the accuracy of monitoring and diagnosis. It also took the lead in putting forward the concept of self-learning dynamic threshold, directly facing the individual differences of equipment, realizing real-time adjustment and automatic adjustment of threshold, accurately identifying and judging the operating status of equipment, and making equipment operation and maintenance more worry free. Summer is a holiday and rest season. How can you stand in front of the equipment in the scorching sun? ABB's diversified user interaction means make you no longer have to wait on the site to the end. Remote information interaction can also be carried out conveniently, and you can easily enjoy the midsummer without being bound by work.

ABB digital intelligent ring main cabinet (safe digital) can freely access ABB ability ™ The cloud platform realizes remote access to data, and multiple data viewing ways allow you to control the equipment at any time and anywhere: you can view all equipment operation data and equipment health status through the display screen on the cabinet; It can scan the QR code, use the mobile phone to connect to the WiFi of the smart terminal, and monitor the real-time data through the mobile phone browsing device; You can take the express train of "cloud edge integration" through ABB ability ™ Cloud platform (or customer private platform) to view data. The important event information is timely pushed to the mobile phone number subscribed by the customer to realize the "zero delay" of the equipment status. ABB digital intelligent ring main cabinet safe digital not only has superior performance, but also takes into account the easy replacement in the design, which is convenient for the upgrading and transformation of secondary equipment. Through simpler planning and less transformation investment, the cost of the whole life cycle of equipment can be reduced, the health of customers' assets can be fully protected, and the investment value of customers' assets can be improved.

Touch screen panel with excellent TFT / LED display color and multi protocol connectivity. They are easy-to-use HMIS with comprehensive and integrated templates and libraries for every possible process you need. All standard panels are equipped with high-resolution graphics in TFT / LED displays. Most models offer a wide screen, high-resolution display to improve efficiency and excellent operator interaction.

Author: Yishan Yihai

Link:

Source: Zhihu

The copyright belongs to the author. For commercial reproduction, please contact the author for authorization. For non-commercial reproduction, please indicate the source. Fully deployable HMI with comprehensive and integrated templates and libraries for every conceivable process. Panel builder tool has familiar Microsoft ® Windows ® Environment and multi language support can realize fast, simple and efficient engineering design. 81001-450-53-r when writing this field, timer 4 loads the edge of the written value timer clock at the next rise, whether the timer is enabled or disabled. The value stored in this register will also be automatically reloaded (or timed out) when the terminal counts. When reading any field, the current count value is locked and returned. There are two modes to determine how to lock the count, depending on the "read latch select" bit in the WDT control status register (csr2). See csr2 for more information on these two modes, see the registration instructions. When reading this field, the current count value is locked and returned. There are two modes to determine how to lock the count, depending on the "read latch select" bit in the WDT control status register (csr2). See csr2 for more information on these two modes, see the registration instructions. Timer 4 current count register (tmrccr4) the current count of timer 4 can be read through the timer 4 current count register (tmrccr4), located at the offset 0x28 of address in bar2 81001-450-53-r A-B high voltage inverter module

1. Central processing unit (CPU)

The central processing unit (CPU) is the control center of PLC. It receives and transmits the data according to the functions given by the PLC system program

Store user programs and data input from the programmer and check the status of power supply, memory, VO and alarm timer,

It can also diagnose syntax errors in the user program: when the PLC is put into operation, it first receives the field inputs in the form of scanning

Enter the status and data of the device, and store them in the IO image area, and then read the user program from the user program memory one by one

After the command is interpreted, the result of logical or arithmetic operation is sent to the VO image area or data register according to the instruction

Inside. After all user programs are executed, the output states or output registers of the 1 / O image area are finally

The data is transmitted to the corresponding output device, and the operation is repeated until the operation is stopped.

In order to further improve the reliability of PLC, in recent years, large-scale PLC has also adopted Dual CPU to form redundant system, or

Voting system with three CPUs. In this way, even if a CPU fails, the whole system can still operate normally.

2. Memory

The memory storing system software is called system program memory.

(1) Memory type commonly used by PLC.

1) RAM (Random Assess Memory)。 This is - a read / write memory (random access memory) whose access speed

The fastest speed, supported by Keng battery.

2) EPROM (Erasable Progranmable Read Only Memory)。 This is an erasable read-only storage

All contents in the memory remain unchanged when the device is powered off (the memory contents can be erased under continuous ultraviolet irradiation).

3) EPROM (Electrical Erasable Programmable Read Only Memory)。 This is an electrically erasable

Read only memory except. The stored contents can be easily modified by using the programmer.

(2) Allocation of PLC storage space. Although the maximum address space of the CPUs of various PLCs is different

According to the working principle of PLC, its storage space generally includes the following three areas: system program storage area and system RAM storage

Area (including I / O image area and system software equipment), user program storage area.

1) System program storage area. A system program corresponding to the computer operating system is stored in the system program storage area,

Including monitoring program, management program, command interpretation program, function subprogram, system diagnosis subprogram, etc. By the manufacturer

It is solidified in EPROM and cannot be directly accessed by the user. It determines the performance of the PLC together with the hardware.

2) System RAM storage area. System RAM storage area includes I / O image area and various soft devices, such as logic

Coils, data registers, timers, counters, index registers, accumulators and other memories. Configuration control technology is a kind of computer control technology. It is to use the computer to monitor certain equipment to make it work according to the control requirements. The computer configuration monitoring system composed of configuration control technology is mainly composed of controlled objects, sensors, I / O interfaces, computers and actuators.

This training is based on the MCGS configuration software platform to complete the man-machine interface production and program design of the configuration monitoring system. MCGS (monitor and Control Generated System) configuration software is a configuration software system based on the window platform developed by Beijing Kunlun Tongtai Software Co., Ltd., which is used to quickly construct and generate the upper computer monitoring system. Through the collection and processing of on-site data, the development platform for solving practical engineering problems is provided to users by means of animation display, alarm processing, process control, report output, etc.

Because it is a software developed by Chinese people, it is all Chinese and very suitable for our use. In addition, it can provide nearly 100 kinds of drawing tools and basic symbols, quickly construct graphical interfaces, and also provide thousands of exquisite library elements and progressive colors

The animation mode can quickly build beautiful animation, and it also supports temperature control curve, plan curve, time real curve, history curve, XY and other industrial control curves. In short, MCGS software can quickly complete the development of a computer monitoring and control system with stable operation, mature function, small maintenance and professional level. Next, I will introduce the detailed process of using MCGS configuration software to complete the task, the problems encountered and the solutions.

Task 1: pump operation control

Open the MCGS general configuration software, and we will see five parts, namely, main control window, equipment window, user window, real-time database and operation strategy.

First, we will create a new project, name it the pump control system and save it.

Then open the user window to complete the establishment of relevant symbols. The teacher first established a real-time database when building the project, because he has a clear understanding of the control attributes of symbols, so for beginners, drawing symbols first is the first choice.

(1) Create a new window 0 in the user window, rename it to the pump operation control, and create an animated title "pump control" with a label in the animation window

(2) Draw pump

In the software, we have been provided with an "object original library" in which we can select the original we want, so next, we add a "pump 30" icon and confirm it. The size of the icon can be adjusted to achieve a beautiful effect

(3) Add two "buttons" under the pump to change the name to "start" and "stop" respectively. You can also double-click to change the background color of the button.

(4) Two more indicator lights are added to show the status of stop and start. In order to show the status of start and stop more clearly, you can also transform an indicator light yourself. The transformation method is to first use the indicator light provided by a library as the transformation object, first decompose the unit, and then drag the first icon away, Break down the bottom icon, change its color, add a "visibility" attribute and fill in the expression with @ switch value, and then set the related attributes of the other indicator light.

(5) In order to display the time, we add two buttons, namely "timer start" and "timer reset", and add two labels, namely, to control "timer time" and "time to".

(6) Add four input boxes to set their attributes to numeric type,

(7) Now let's add the relevant data in the real-time database. They are water pump, start, reset, timer start and timer reset. The "timer time" and "time to" are numeric.

(8) After the establishment of real-time data, we can associate the relevant expressions of the icons in the user window. Since there is time control, we need to add a timer and a script program in the operation strategy. Set the time value to 35 seconds in the timer attribute, and write the control program with the if-then statement in the script program. Remember to use exit to divide the steps. Before entering the running environment test, adjust the content of the cycle strategy and change the timing cycle time to 200s.

Task 2: water pump operation monitoring

In the early stage, only the "equipment independence" of the MCGS system was used in the water pump control configuration project with the help of timer and script strategy to initially realize the simulation operation of the water pump control system, which did not achieve the purpose of real-time monitoring. Therefore, the monitoring setting is required next.

We know that the pump operation control is mainly controlled by PLC, while the MCGS system, on the one hand, needs to collect relevant data from the PLC, change the value of the corresponding variable in the real-time database, and then display it in the animation form of the icon component in the screen, so as to achieve the purpose of monitoring the operation; On the other hand, it is also necessary to write the pause and running time set in the upper computer configuration environment into the PLC to adjust the running time of the water pump, and to control the operation and stop of the water pump hardware system through the start and stop buttons of the upper computer.

Open the previous "task 1" and save it as "water pump operation monitoring" to improve the "task 1" configuration engineering animation and attribute settings.

(1) Delete timer policy and script policy. [when online, PLC completes the control task, so the configuration Engineering

The timer and script programs in are useless]

(2) Modify the four data objects related to timers in the database, namely "timer start" and "timer reset" to count the time and time to improve the efficiency of the operating environment. Then add four new data objects, namely "run time display", "run time adjustment", "pause time display" and "pause time adjustment". The object type is numeric.

(3) Delete the icon related to the timer in the "animation configuration water pump control" window, and make 6 new text labels.

(4) Create the animation window as shown in the figure

安全提示:

请勿随意接收任何来源不明的文件,请勿随意点击任何来源不明的链接。涉及资金往来的事项请务必仔细核对资金往来信息。

X

¥45455.0

库存:8